China Self Supported Cable Fiber Optic: GYXY 2-12 Core

Product Main Parameters

| Cable Type | GYXY |

|---|---|

| Fiber Count | 2-12 |

| Cable Diameter (mm) | 9.5 - 10.2 |

| Cable Weight (kg/km) | 90 - 100 |

| Tensile Strength Long/Short Term (N) | 600/1500 - 1000/3000 |

| Crush Resistance Long/Short Term (N/100mm) | 300/1000 - 1000/3000 |

| Bending Radius Static/Dynamic (mm) | 10D/20D |

| Temperature Range | -40℃ to 70℃ |

Common Product Specifications

| Optical Characteristics | G.652, G.655 |

|---|---|

| Attenuation @1310nm | ≤0.36 dB/km |

| Attenuation @1550nm | ≤0.22 dB/km |

| Bandwidth @850nm | ≥500 MHz·km |

Product Manufacturing Process

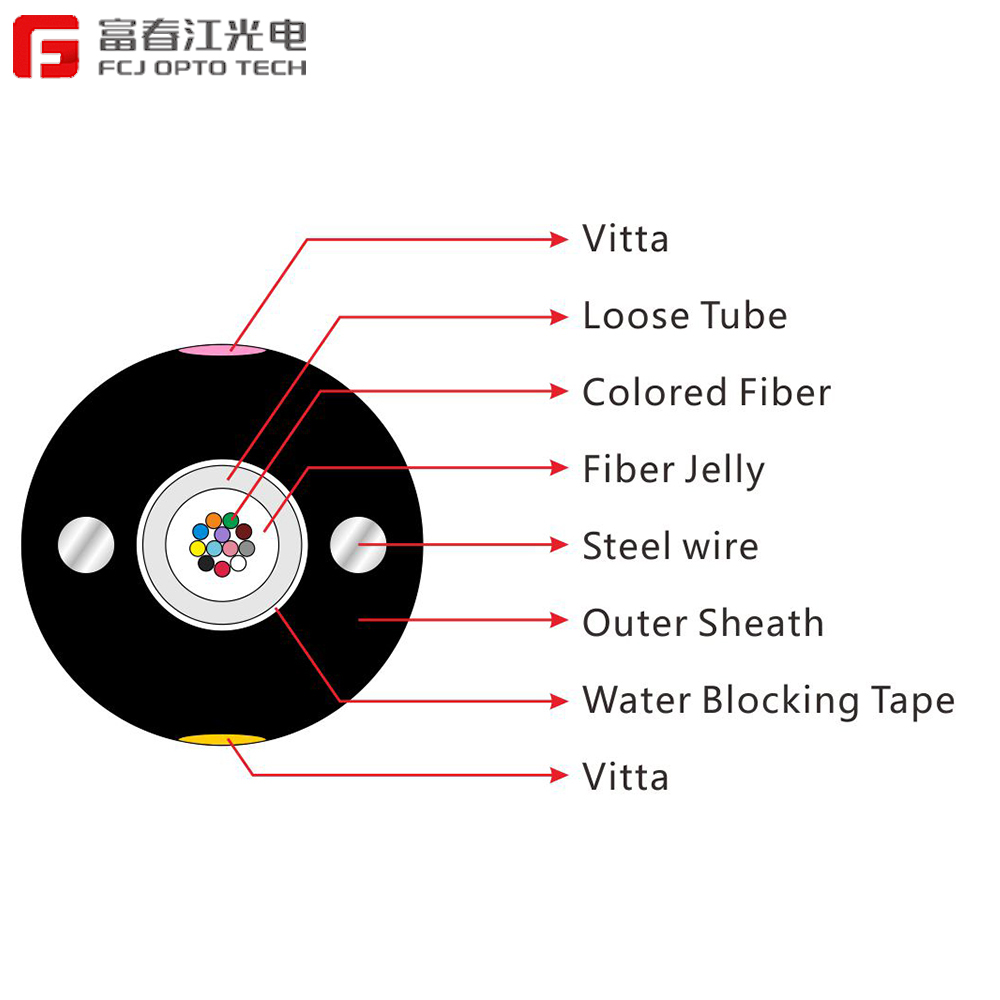

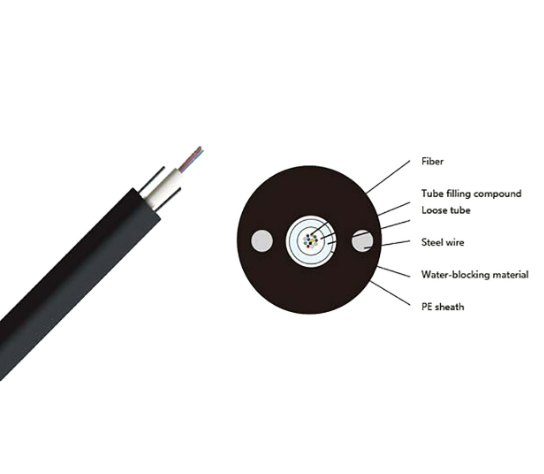

The manufacturing process of China Self Supported Cable Fiber Optic involves several stages. Initially, high-quality raw materials such as silica for optical fibers and polyethylene for jacketing are sourced. Optical fibers are produced through a sophisticated drawing process, where preforms are heated and drawn into ultra-thin strands. These fibers are then coated with a protective layer to enhance durability. Next, the fibers are assembled into loose or tight buffer tubes, filled with water-blocking compounds to prevent moisture ingress. Strength members, often made from aramid yarn or fiberglass, are integrated into the design to provide structural integrity and support. Finally, an outer PE sheath is applied, offering UV, moisture, and physical protection. Quality control is maintained throughout the process, ensuring compliance with international standards and providing optimal performance and reliability.

Product Application Scenarios

China Self Supported Cable Fiber Optic is versatile, making it suitable for various scenarios. In telecommunications, it facilitates high-speed data transfer over long distances, efficiently linking networks across vast geographical areas. In power utilities, its dielectric nature ensures safe installation alongside power lines, minimizing interference risks. Similarly, railways and transportation sectors benefit from its robust design, enabling reliable communication systems. Due to its self-supporting feature, this cable is ideal for aerial deployments, especially where long spans need bridging. Additionally, its strength and environmental resistance make it a preferred choice in challenging environments, ensuring uninterrupted connectivity.

Product After-sales Service

We offer comprehensive after-sales support for our China Self Supported Cable Fiber Optic products. Our team is available to assist with any inquiries or issues, providing expert guidance and technical assistance to ensure optimal product performance. Customers can rely on our dedicated service for troubleshooting, maintenance advice, and warranty claims.

Product Transportation

Transportation of China Self Supported Cable Fiber Optic is handled with utmost care. We use secure packaging to protect the cables from physical damage and environmental factors during transit. Our logistics partners are experienced in handling delicate technology products, ensuring timely and safe delivery to any location worldwide. Customers can track their shipments and receive detailed information on expected delivery times.

Product Advantages

- High tensile strength and durability

- Immune to electromagnetic interference

- UV and moisture resistant

- Cost-effective installation

- Environmentally robust

Product FAQ

- What is the tensile strength of the China Self Supported Cable Fiber Optic? The cable offers a tensile strength of 600/1500 N for long term and 1000/3000 N for short term, ensuring robust performance.

- Can the cable be used alongside power lines?Yes, its dielectric nature makes it safe and interference-free when installed near power lines.

- What environments are suitable for this cable?This cable is suitable for diverse environments, including telecommunications, utilities, and transportation sectors.

- How does the cable withstand weather conditions?It features a PE sheath that protects against UV radiation, moisture, and temperature variations, enhancing durability.

- Is the cable resistant to physical damage?Yes, its construction is designed to withstand environmental stresses without constant maintenance needs.

- What is the expected lifespan of the cable?With proper installation and minimal maintenance, the cable offers a long lifespan, maintaining performance over years.

- What is the bandwidth capacity of the cable?The cable supports a bandwidth capacity of ≥500 MHz·km @850nm.

- Is the installation complex?The self-supporting design simplifies installation, reducing setup time and costs.

- How does the cable handle electromagnetic interference?Its all-dielectric construction ensures immunity to electromagnetic interference, providing reliable performance.

- Can the cable be reused or recycled?Yes, components such as the PE sheath and optical fibers are recyclable, supporting sustainable practices.

Product Hot Topics

- Why Choose China Self Supported Cable Fiber Optic for Telecommunications?Opting for China Self Supported Cable Fiber Optic in telecommunications is a prudent choice due to its exceptional performance attributes. Its robust design ensures high tensile strength, accommodating long spans without additional support, making it ideal for aerial deployments. Additionally, the cable's all-dielectric nature offers immunity to electromagnetic interference, guaranteeing uninterrupted data transmission even in close proximity to power lines. Its moisture-resistant properties prevent water ingress, while UV protection ensures longevity, even under harsh weather conditions. These characteristics, combined with ease of installation and minimal maintenance needs, make it a preferred choice for reliable and cost-effective telecommunications solutions in China and globally.

- How Durable is China Self Supported Cable Fiber Optic in Harsh Environments?China Self Supported Cable Fiber Optic is engineered to thrive in harsh environments, thanks to its durable construction. The outer PE sheath provides a resilient barrier against environmental factors such as UV radiation, moisture, and extreme temperatures. Meanwhile, the water-blocking materials within the buffer tubes enhance moisture resistance, protecting the optical fibers from degradation. Strength members, typically made from aramid yarns or fiberglass, add to the cable's robustness, enabling it to withstand physical stress and damage. As a result, this fiber optic cable maintains its performance over extended periods, ensuring reliable connectivity in challenging settings, both urban and rural.

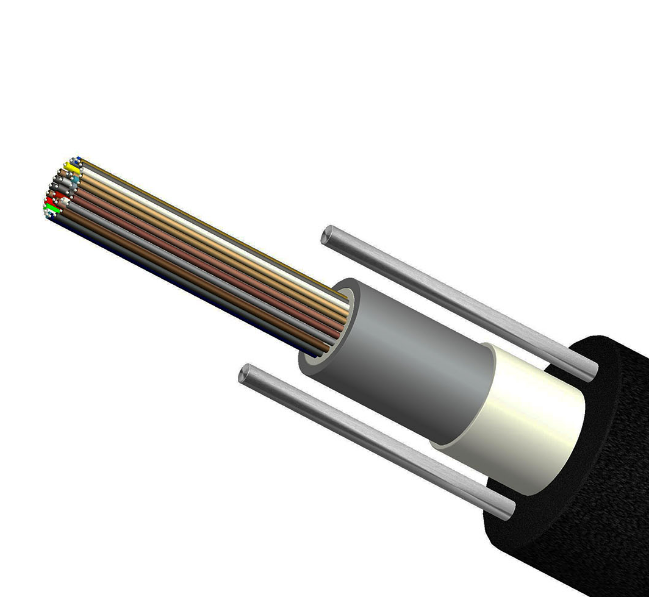

Image Description