Factory Compact Connector Indoor Cable 12/24 Core

Product Main Parameters

| Fiber Count | Tight Buffer Diameter (mm) | Cable Diameter (mm) | Cable Weight (Kg/km) | Tensile Strength Long/Short Term (N) | Crush Resistance Long/Short Term (N/100m) | Bending Radius Static/Dynamic (mm) |

|---|---|---|---|---|---|---|

| 12 | 0.9 | 12.5 | 124 | 400/800 | 200/1000 | 30D/105D |

| 24 | 0.9 | 13.5 | 158 | 400/800 | 200/1000 | 30D/105D |

Common Product Specifications

| Optical Fiber Type | @850nm | @1300nm | @1310nm | @1550nm | Bandwidth | Numerical Aperture | Cable Cut-off Wavelength |

|---|---|---|---|---|---|---|---|

| G.652 | ≤3.0dB/km | ≤1.0dB/km | ≤0.36dB/km | ≤0.22dB/km | ≥200MHZ·km | 0.200±0.015NA | ≤1260nm |

| G.655 | ≤3.0dB/km | ≤1.0dB/km | - | ≤0.23dB/km | ≥500MHZ·km | 0.275±0.015NA | ≤1480nm |

Product Manufacturing Process

Manufacturing of Compact Connector cables at our factory involves several key processes including sourcing high-quality preforms, fiber drawing, cable stranding, and applying multiple protective layers such as steel armor and PE sheath. According to industry papers, effective manufacturing ensures high tensile strength, flexibility, and excellent signal transmission qualities. Each step is meticulously monitored to maintain industry standards and specifications, ensuring that the end product meets the demands of modern telecommunication needs.

Conclusion

Effective cable manufacturing revolves around precision, quality control, and innovation. Our factory's Compact Connector cables are embodiments of these principles, setting standards in the optical communications industry.

Product Application Scenarios

The application scope for Compact Connector cables is vast due to their robust design and adaptability. In addition to traditional telecommunications, these cables are crucial in FTTH deployments, connecting remote locations with reliable internet. Their compact build and robust protection make them ideal for environments where space is constrained or exposure to physical elements is high, such as in urban infrastructure projects and challenging industrial settings.

Conclusion

Compact Connector cables are strategically vital in advancing telecommunication infrastructures, especially in emerging markets, and are central to the future of seamless global connectivity.

Product After-Sales Service

Our factory offers comprehensive after-sales service, ensuring full support post-purchase. This includes installation guidance, maintenance tips, and warranty services for complete customer satisfaction.

Product Transportation

Transport of Compact Connector cables is managed with precision, employing advanced logistics to ensure delivery schedules are met, and products arrive in pristine condition, ready for deployment.

Product Advantages

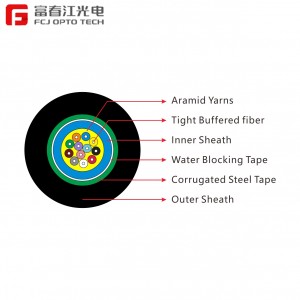

- High tensile strength and crush resistance due to steel armor and aramid yarns.

- LSZH inner jacket ensures safety in case of fire.

- Excellent performance in harsh environmental conditions.

- Versatile applications across various industries.

Product FAQ

- What is the tensile strength of the cable?

The tensile strength is 400 N for long-term and 800 N for short-term applications, ensuring reliability and durability. - Is the cable suitable for outdoor use?

Yes, the steel armored protection makes it suitable for outdoor deployments, protecting against environmental damage. - What are the optical parameters of G.652 fibers?

The attenuation is ≤0.36dB/km at 1310nm, and ≤0.22dB/km at 1550nm, ensuring excellent signal transmission. - How does the factory ensure product quality?

Our factory conducts rigorous quality checks at each manufacturing stage, adhering to international standards. - Can these cables be used in harsh environmental conditions?

Yes, they are designed with high environmental performance, suitable for various challenging installations. - What is the significance of having a LSZH inner jacket?

LSZH (Low-Smoke Zero Halogen) provides enhanced safety in fire-prone environments by minimizing toxic emissions. - Are the cables available in different fiber counts?

Yes, they are available in 12 and 24 core configurations to suit different deployment needs. - What kind of after-sales support is available?

We offer comprehensive support, including installation guidance, troubleshooting, and warranty services. - How are products transported to ensure safety?

We use advanced logistics solutions to ensure timely and secure delivery of products. - What are the bending radius specifications?

The bending radius is 30D for static and 105D for dynamic, ensuring flexibility and longevity.

Product Hot Topics

- How Compact Connector Technology is Revolutionizing Telecommunications at the Factory Level

The adaptability of Compact Connectors is redefining telecommunication standards by enabling high-density installations and more efficient long-distance transmissions. Factory innovations in compact design are integral to this evolution, providing crucial advancements in speed and reliability. - The Role of Factory Innovations in Producing Advanced Compact Connector Cables

At the factory level, precision-engineering and material science breakthroughs are driving the development of Compact Connector cables, essential for modern communication networks. Such innovations ensure high-performance standards and future-ready solutions for global connectivity challenges. - Examining the Environmental Impact of Compact Connectors in Modern Factories

Modern factories are increasingly focusing on sustainability, integrating eco-friendly materials and processes in the production of Compact Connectors. This shift supports environmental goals without compromising on performance or quality. - Factory-Level Challenges in Mass-Production of Compact Connectors

Achieving consistency, quality, and scale in manufacturing Compact Connectors involves overcoming significant challenges. Factories must balance cost-efficiency with technological innovation to meet global demand. - Future Trends: The Evolution of Compact Connector Technology in Factories

Factory advancements in Compact Connector technology are continually evolving, driven by demands for miniaturization, increased functionality, and adaptability. These trends signal a significant shift towards more sophisticated telecommunication environments. - The Importance of Quality Control in Compact Connector Factory Production

Quality control is crucial in the factory production of Compact Connectors to ensure that each product meets stringent industry standards. It encompasses rigorous testing and validation processes at every production stage. - Cost Efficiency in Compact Connector Manufacturing: A Factory Perspective

Factories are implementing more efficient processes and technologies to produce Compact Connectors cost-effectively. These strategies include lean manufacturing principles and innovative automation technologies. - The Impact of Global Supply Chains on Compact Connector Availability from Factories

Global supply chains significantly influence the availability of Compact Connectors from factories. Understanding these dynamics is crucial for managing production cycles and meeting international demand efficiently. - Advancements in Factory Automation for Compact Connector Production

Factory automation is transforming Compact Connector production, enhancing precision, reducing errors, and increasing output capacity, making it a critical factor in meeting rising industry demands. - Exploring the Integration of AI in Compact Connector Factory Manufacturing

Artificial Intelligence (AI) is increasingly integrated into factory processes, optimizing Compact Connector manufacturing through predictive maintenance, quality control, and process automation, leading to superior products.

Image Description

There is no picture description for this product