Factory-Direct Buried Fiber Optic Cable: GJSFJBV Duplex

Product Main Parameters

| Parameter | Details |

|---|---|

| Central Strength Member | Steel/fiberglass |

| Optical Fiber | Single Mode, 2 Core |

| Outer Sheath | PVC/LSZH |

| Buffer Diameter | Ф900μm or Ф600μm |

Common Product Specifications

| Specification | Value |

|---|---|

| Attenuation @1310nm | ≤0.36dB/km |

| Bandwidth @850nm | ≥500MHZ·km |

| Storage/Operating Temperature | -20℃ to 60℃ |

Product Manufacturing Process

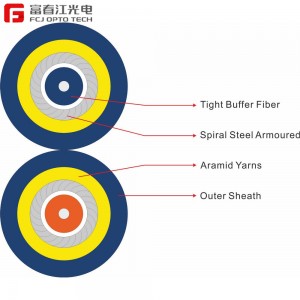

The manufacturing of Direct Buried Fiber Optic Cable involves precise layering of materials to ensure durability. According to authoritative sources, the process begins with the careful selection of optical fibers, which are then buffered to protect against external forces. The fibers are bundled with a central strength member to provide structure. The next layer involves wrapping with aramid yarn for tensile strength, followed by a robust outer sheath for environmental protection. The inclusion of corrosion-resistant materials enhances longevity, especially in challenging terrains. Studies indicate that the meticulous adherence to these steps ensures a product with exceptional performance and reliability in field applications, emphasizing the factory's commitment to quality.

Product Application Scenarios

Direct Buried Fiber Optic Cables are integral to modern communication networks. As noted in authoritative studies, they are widely used in telecommunications, providing the backbone for data and voice transmission in both rural and urban areas. In utility sectors, these cables help in grid management and monitoring. Their robust construction makes them ideal for military and government communications, ensuring secure and reliable data transfer. The factory's dedication to enhancing the cable's protective layers has made them suitable for harsh environments, further expanding their applicability. This adaptability to various scenarios demonstrates their critical role in infrastructure development.

Product After-Sales Service

We ensure a seamless after-sales experience for our Direct Buried Fiber Optic Cable clientele. Our dedicated support team is available to assist with installation guidance, troubleshooting, and maintenance advice. Customers can access our comprehensive resource library for technical documentation and FAQs. We offer warranty services for manufacturing defects and ensure rapid response times for support requests. Ensuring customer satisfaction and operational efficiency remains our top priority in line with our factory's service standards.

Product Transportation

The Direct Buried Fiber Optic Cable is securely packaged to withstand the rigors of transportation. Our logistics partners ensure timely and safe delivery across continents, adhering to international shipping standards. Each shipment includes detailed packaging labels and handling instructions to minimize damage during transit. Our factory's logistical efficiency ensures that product delivery is streamlined, enabling quick deployment upon receipt. Clients can track their orders online, providing transparency and peace of mind during the shipping process.

Product Advantages

- Cost-effective installation by avoiding conduit use.

- Rapid deployment with straightforward trenching methods.

- Enhanced protection against environmental and physical damage.

- Flexible design accommodates a variety of connectivity needs.

Product FAQ

- What is the optimal burial depth for these cables? For Direct Buried Fiber Optic Cable, burial depth should consider local regulations and surface activity, generally ranging from 0.8 to 1.2 meters to reduce risk from heavy machinery.

- Can this cable be used in both urban and rural setups? Yes, its robust design makes it suitable for diverse environments, providing reliable performance in both dense cityscapes and remote areas.

- Does the cable require additional protection during installation? No, the factory design ensures the cable's durability with inherent layers of protection, making it self-sufficient for direct burial.

- How does the factory address cable longevity in harsh conditions? Our manufacturing process includes high-quality materials that resist corrosion, moisture, and temperature fluctuations, extending the cable's lifespan.

- What installation equipment is recommended? Specialized trenching machines or plows are recommended to ensure precise and safe installation of the Direct Buried Fiber Optic Cable.

- What kind of maintenance does this cable require? Routine inspection of the installation site suffices; the cable's construction minimizes maintenance needs, ensuring long-term reliability.

- How is this cable protected against rodent damage? Its metal armor layer acts as a deterrent to rodents, safeguarding the internal fibers from potential damage.

- What are the temperature tolerances of this cable? The cable functions efficiently between -20℃ and 60℃, making it suitable for diverse climatic conditions.

- How does the factory ensure quality in manufacturing? Our production process adheres to international standards like IEC794, ensuring each cable's performance and durability.

- What warranty does the factory offer? We offer a standard warranty covering manufacturing defects, details of which are provided with product documentation.

Product Hot Topics

- How do Direct Buried Fiber Optic Cables impact today's telecommunication infrastructure? These cables are revolutionizing telecommunications by offering cost-effective, robust solutions for high-speed data transmission over long distances. Their ability to be directly buried reduces installation time and costs significantly. Telecom companies value this approach, as it optimizes network expansion efforts, particularly in rural and developing regions. The factory's expertise in producing these cables ensures they meet the demanding needs of modern network infrastructures, contributing to seamless connectivity and enhanced communication services globally.

- What sets this product apart from traditional fiber optic cables? Direct Buried Fiber Optic Cables are uniquely designed to withstand harsh environmental factors without additional protection. Unlike traditional cables that require conduits, these cables integrate robust materials capable of enduring physical stress, moisture, and temperature variations. Our factory's innovation in design and material selection plays a crucial role in providing a product that aligns with the growing demand for reliable and durable communication solutions, setting a new standard in cable technology.

Image Description

There is no picture description for this product