Factory Direct FRP Strength Member for Fiber Optic Cables

Product Main Parameters

| Parameter | Specification |

|---|---|

| Fiber Count | 2, 4, 6, 8, 12 |

| Cable Diameter | 2.0mm×5.0mm / 2.5mm×6.0mm |

| Operating Temperature | -20℃ to 60℃ |

Common Product Specifications

| Specification | Details |

|---|---|

| Sheath Material | LSZH |

| Tensile Strength | Long: 300N, Short: 600N |

| Crush Resistance | 1000 N/100mm - 2200 N/100mm |

Product Manufacturing Process

The manufacturing of FRP Strength Member for Fiber Optic Cables involves advanced composite technology, where glass or aramid fibers are embedded in a polymer matrix. This process ensures high tensile strength, flexibility, and environmental resistance. According to industry standards, the manufacturing process includes fiber impregnation, curing, and testing stages to ensure the final product meets telecom specifications and performance requirements. Sources such as the Journal of Composite Materials highlight the importance of controlled production environments to maintain quality and consistency.

Product Application Scenarios

FRP Strength Member for Fiber Optic Cables finds applications in various scenarios including telecommunications, high-speed internet, and industrial environments. Authoritative sources such as the IEEE Journal of Optical Communications emphasize its role in enhancing cable longevity and reliability, particularly in adverse weather conditions or areas prone to electrical interference. The non-metallic nature of FRP makes it ideal for use in buried and aerial installations where electrical safety is paramount.

Product After-Sales Service

Our factory provides comprehensive after-sales support including installation guidance, troubleshooting, and replacement of defective parts under warranty. We ensure customer satisfaction through prompt response and technical assistance.

Product Transportation

We ensure safe and efficient transportation of our FRP Strength Member cables, using robust packaging to protect against physical damage during transit, with options for both local and international shipping.

Product Advantages

- High tensile strength ensuring resistance to breakage.

- Environmentally resistant for long-lasting performance.

- Lightweight and easy to handle.

Product FAQ

- What is the primary function of the FRP strength member?

It provides tensile strength and protection to fiber optic cables, ensuring performance stability even under tension.

- How does FRP compare to steel in cable applications?

FRP is lighter, non-conductive, and corrosion-resistant, offering safety and longevity advantages over steel.

Product Hot Topics

- Topic 1

Discussing the benefits of factory direct FRP Strength Member for Fiber Optic Cables in modern telecom infrastructures. Clients appreciate the enhanced durability and lightweight nature which reduce installation efforts and costs.

- Topic 2

Addressing sustainability in cable manufacturing, our factory integrates eco-friendly practices with FRP Strength Member for Fiber Optic Cables, aligning with global green initiatives while maintaining product integrity and performance.

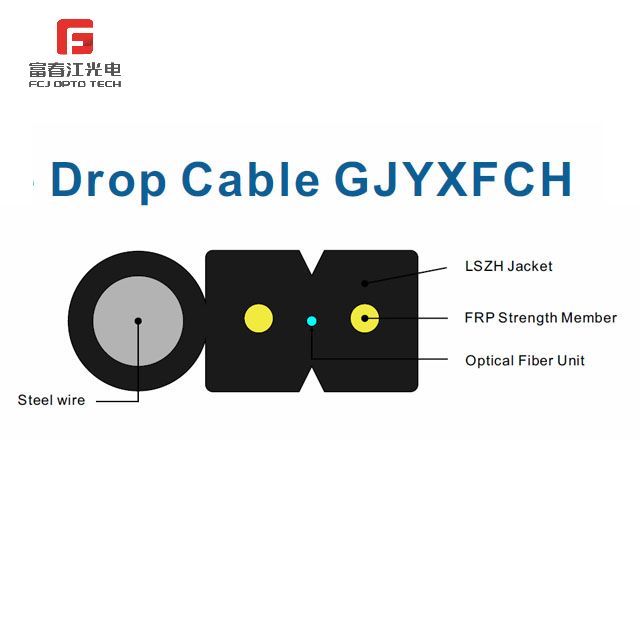

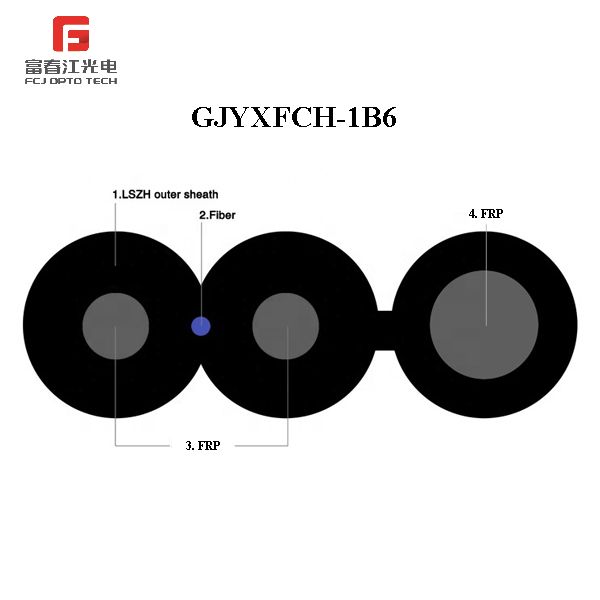

Image Description