Factory Direct FRP Strength Member for Fiber Optic Cables

Product Main Parameters

| Fiber Count | Cable Diameter (mm) | Cable Weight (kg/km) | Tensile Strength Long/Short Term (N) | Crush Resistance Long/Short Term (N/100mm) | Bending Radius Static /Dynamic (mm) |

|---|---|---|---|---|---|

| 1 | (2.0±0.)×(5.0±0.2) | 20 | 300/600 | 1000/2200 | 20/40 |

| 2 | (2.0±0.2)×(5.0±0.2) | 20 | 300/600 | 1000/2200 | 20/40 |

Common Product Specifications

| Attenuation (20℃) | @850nm | @1300nm | @1310nm | @1550nm |

|---|---|---|---|---|

| ≤3.5 dB/km | ≤3.5 dB/km | ≤1.5 dB/km | ≤0.40 dB/km | <≤0.30 dB/km |

Product Manufacturing Process

FRP Strength Member production involves embedding high-strength fibers like E-glass or aramid into a polymer matrix, typically a thermoset resin such as epoxy. This composite material is then cured at high temperatures to ensure structural integrity and performance. According to authoritative studies, this process provides unmatched tensile strength and corrosion resistance compared to traditional metallic alternatives.

Product Application Scenarios

FRP Strength Members are crucial in various applications including indoor cables for easy routing, outdoor cables for withstanding environmental stress, and submarine cables where corrosion resistance is vital. As highlighted in industry papers, their non-magnetic properties make them ideal for sensitive data transmission environments.

Product After-Sales Service

Our after-sales service includes comprehensive support through warranty periods, technical assistance, and product replacement in case of defects arising from manufacturing faults. Customers can rely on our factory's dedicated support team for timely resolution of any issues.

Product Transportation

Our logistics team ensures safe and timely delivery of the FRP Strength Member for Fiber Optic Cables, adhering to international shipping standards to ensure product integrity during transit.

Product Advantages

- High tensile strength

- Corrosion resistance

- Lightweight and flexible

- Excellent thermal and electrical insulation

Product FAQ

- What are FRP Strength Members?

FRP Strength Members are essential components in fiber optic cables, providing strength and flexibility, produced by embedding fibers like E-glass or aramid in a polymer matrix.

- Why choose factory-made FRP Strength Members?

Our factory ensures the highest quality control standards, producing FRP Strength Members that are strong, reliable, and competitively priced for various telecom applications.

Product Hot Topics

- Why is FRP Strength Member preferred over metallic alternatives?

The factory-produced FRP Strength Member offers superior corrosion resistance and weight advantages, making it ideal for long-term deployments in harsh environments without suffering from degradation.

- How does the factory ensure consistent quality in FRP Strength Members?

At our factory, stringent quality control processes are in place, with dedicated testing facilities to verify each batch's compliance with international standards, ensuring reliability and performance in all conditions.

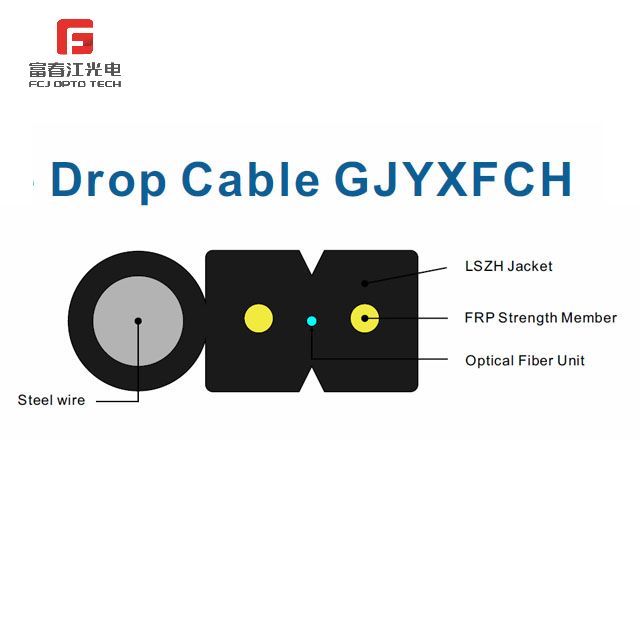

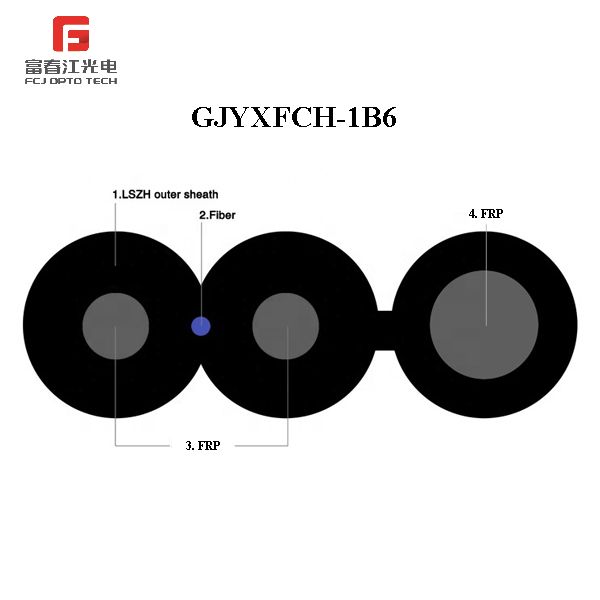

Image Description