Factory-Grade Fiber Optic Cable Splitter Device

Product Main Parameters

| Parameter | 1×N | 2×N |

|---|---|---|

| Wavelength (nm) | 1260~1650 | 1260~1650 |

| Fiber Type | G657A 1 | G657A 2 |

| Insertion Loss (dB) | ≤3.8-23.5 | ≤4.2-23.8 |

Common Product Specifications

| 1×N | 2×N | |

|---|---|---|

| Pigtail Length (m) | 1.0(±0.1) | 1.0(±0.1) |

| Return Loss (dB) | ≥55 | ≥55 |

Product Manufacturing Process

Fiber optic cable splitters are manufactured through a complex process that involves the combination of optical fibers and planar lightwave circuit technology. The process begins with the selection of high-purity raw materials to form the optical fibers. These fibers are then precisely aligned within a PLC wafer using advanced lithography. The alignment ensures minimal signal loss and high-performance output. Once aligned, the fibers are encapsulated within a protective casing to shield against environmental damage. The final product undergoes rigorous testing to ensure compliance with industry standards such as Telcordia and RoHS. This well-orchestrated manufacturing process results in a highly reliable product suitable for industrial and commercial applications.

Product Application Scenarios

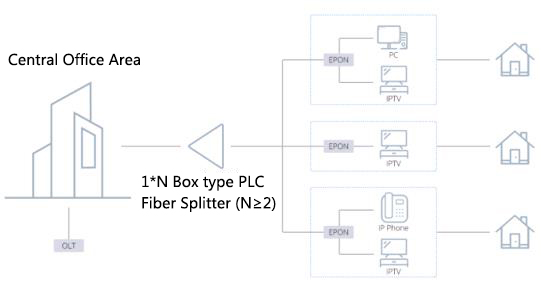

Fiber optic cable splitters play an essential role in modern telecommunication networks. They are primarily used in scenarios where a single optical signal needs to be distributed to multiple endpoints, such as in Fiber-to-the-Home (FTTH) systems, Passive Optical Networks (PON), and CATV networks. Their ability to split signals efficiently makes them indispensable in high-density networking environments, including data centers and urban communication infrastructure. By distributing optical signals without significant loss, they ensure efficient data transmission across long distances, serving as a backbone for global telecommunication systems.

Product After-Sales Service

Our factory offers comprehensive after-sales support for our fiber optic cable splitters, ensuring customer satisfaction and product longevity. This includes technical assistance, warranty services, and replacement policies, all managed by our experienced support team.

Product Transportation

Our fiber optic cable splitters are packaged securely to withstand transportation stress. We ensure that all products are delivered to our customers via trusted logistics partners to maintain product integrity and timely delivery.

Product Advantages

- High Bandwidth: Capable of handling large data volumes efficiently.

- Low Signal Loss: Maintains effective communication over long distances.

- Electromagnetic Immunity: Unaffected by EMI, ensuring reliable data transmission.

- Security: Offers enhanced data protection due to the nature of fiber optic technology.

Product FAQ

- What makes fiber optic cables superior to copper cables?

Fiber optic cables offer higher bandwidth, faster data transmission speeds, greater signal integrity over long distances, and immunity to electromagnetic interference, making them superior to traditional copper cables. - How are fiber optic cables manufactured in the factory?

The manufacturing process involves drawing glass or plastic into fibers, coating them for protection, and assembling them into cables. This precise process ensures minimal signal loss and high reliability. - Can fiber optic cables be used in extreme temperatures?

Yes, our fiber optic cables are designed to operate within a wide temperature range of -40 to 85 degrees Celsius, making them suitable for various environmental conditions. - Are fiber optic cables safe from cyber threats?

Yes, intercepting data from fiber optic cables is significantly more challenging than from copper cables, making them a safer option against cyber threats. - What maintenance is needed for fiber optic networks?

Fiber optic networks require minimal maintenance, primarily involving periodic inspections to ensure connectors and cables are intact and free from physical damage. - Can existing copper networks be upgraded to fiber optics?

Yes, many telecommunications networks are transitioning to fiber optics to improve speed and capacity, offering enhanced performance over existing copper networks. - How long do fiber optic cables last?

Due to their robust construction and immunity to environmental factors, fiber optic cables can last for several decades when properly installed and maintained. - What is the typical installation process for fiber optic cables?

Installation involves laying cables in designated paths, connecting them to network equipment, and testing to ensure optimal performance. Professional installation is recommended for best results. - How does fiber optic cable capacity compare to wireless technology?

Fiber optic cables offer far greater data capacity and stability compared to wireless technologies, which are affected by distance and physical barriers. - What are the benefits of using fiber optic cables in industrial applications?

In industrial settings, fiber optic cables provide high-speed data transmission, reduced electromagnetic interference, and improved security, facilitating efficient and reliable operations.

Product Hot Topics

- Emerging Trends in Fiber Optic Cable Manufacturing

The fiber optic cable industry is witnessing remarkable advancements with new materials and manufacturing processes that enhance performance and reduce costs. Factories are focusing on developing eco-friendly solutions while maintaining superior product quality. Automation and AI are playing a crucial role in improving production efficiency and precision in cable design, enabling faster deployment and integration into existing systems. These trends signify a growing demand for fiber optic technology, particularly in high-speed internet and global communication sectors. - The Role of Fiber Optic Cables in Smart City Infrastructure

Fiber optic cables are a fundamental component in developing smart city infrastructure, providing the necessary backbone for high-speed data communication. Factories are supplying advanced fiber optic solutions to support IoT applications, smart grids, and intelligent transportation systems. The scalability and reliability of fiber optics make them ideal for connecting various smart city elements, ensuring efficient data exchange and real-time monitoring. As cities worldwide aim to enhance livability through technology, the demand for robust fiber optic networks continues to grow significantly. - Fiber Optic Cables and the Future of Telecommunications

The future of telecommunications is heavily reliant on fiber optic technology due to its unparalleled data transmission capabilities. Factories are pushing the boundaries by innovating with new fiber designs that support higher bandwidth and faster speeds. As 5G and beyond become standard, fiber optic cables will play a pivotal role in backhauling massive data generated by next-gen devices and applications. The continual improvement in fiber optic manufacturing indicates a bright future for the telecommunications industry, with opportunities for enhanced connectivity and integration. - Challenges in Fiber Optic Cable Deployment

Despite the advantages, deploying fiber optic cables presents challenges such as high installation costs, the need for skilled labor, and regulatory hurdles. Factories are addressing these issues by developing cost-effective solutions and offering training programs to increase workforce expertise. Innovations in installation techniques, such as micro-trenching and aerial deployment, are helping to mitigate these challenges, making fiber optic technology more accessible. Overcoming these obstacles will be critical in expanding fiber optic networks to underserved and remote areas. - The Environmental Impact of Fiber Optic Cables

Fiber optic cables are seen as a more environmentally friendly option compared to traditional copper wiring. Factories are actively working to reduce the carbon footprint of fiber optic production by adopting sustainable practices and sourcing eco-friendly materials. Strategies like recycling old cables and minimizing energy consumption during manufacturing contribute to the green credentials of fiber optics. As environmental concerns gain prominence, the shift towards sustainable fiber optic solutions is expected to continue, driving innovation in the industry. - Innovative Materials in Fiber Optic Cable Production

Research and development are paving the way for innovative materials in fiber optic cable manufacturing. Factories are experimenting with materials that offer better performance, durability, and cost-effectiveness. Developments in polymers and glass composites are enhancing the flexibility and strength of fiber optic cables, making them suitable for a wider range of applications. These advancements highlight the dynamic nature of the fiber optic industry, which is continuously evolving to meet the demands of modern communication networks. - The Impact of Industry 4.0 on Fiber Optic Manufacturing

Industry 4.0 technologies are transforming fiber optic manufacturing, with factories adopting automation, IoT, and AI to enhance production efficiency and quality. These technologies enable real-time monitoring and predictive maintenance, reducing downtime and optimizing resource allocation. As the industry embraces digitalization, fiber optic manufacturing is set to become more agile and responsive to market demands, ensuring the delivery of high-quality products with greater consistency and speed. - Global Fiber Optic Cable Market Trends

The global fiber optic cable market is experiencing robust growth driven by increasing demand for high-speed internet and digital communication. Factories around the world are expanding production capacities to cater to diverse markets ranging from telecommunications to healthcare and defense. The rise in cloud computing and data center developments further fuels the demand for fiber optic cables, reinforcing their importance in the global communication infrastructure. This growth trend is expected to persist as technology continues to evolve rapidly. - Ensuring Quality in Fiber Optic Cable Production

Quality assurance is a critical aspect of fiber optic cable production. Factories implement stringent testing protocols to ensure the consistency and reliability of their products. Advanced testing equipment is used to monitor parameters such as signal loss, bandwidth, and durability. By adhering to international standards and continually improving processes, manufacturers ensure that their fiber optic cables meet the highest performance criteria, providing customers with dependable solutions for their networking needs. - Fiber Optic Cables vs. 5G Wireless Technology

Fiber optic cables and 5G represent complementary technologies, each with its advantages. Factories provide fiber optic solutions that serve as the backbone for 5G networks, enabling high-speed data transmission. While 5G offers wireless convenience, fiber optics ensures stable, high-capacity data links that are immune to interference. Together, they form the foundation of modern communication networks, supporting a wide range of applications from mobile connectivity to industrial automation.

Image Description