GJXFH 1 2 4 Core Branch Cable Manufacturer's Choice

Product Main Parameters

| Fiber Count | Cable Diameter (mm) | Cable Weight (kg/km) | Tensile Strength (N) | Crush Resistance (N/100mm) | Bending Radius (mm) |

|---|---|---|---|---|---|

| 1 | (2.0±0.2)×(3.0±0.2) | 8 | 40/80 | 500/1000 | 20/40 |

| 2 | (2.0±0.2)×(3.0±0.2) | 8 | 40/80 | 500/1000 | 20/40 |

| 4 | (2.0±0.2)×(3.0±0.2) | 8 | 40/80 | 500/1000 | 20/40 |

Common Product Specifications

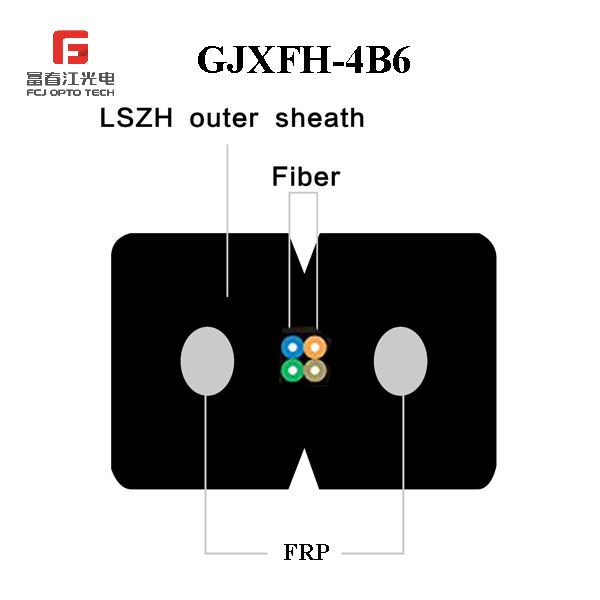

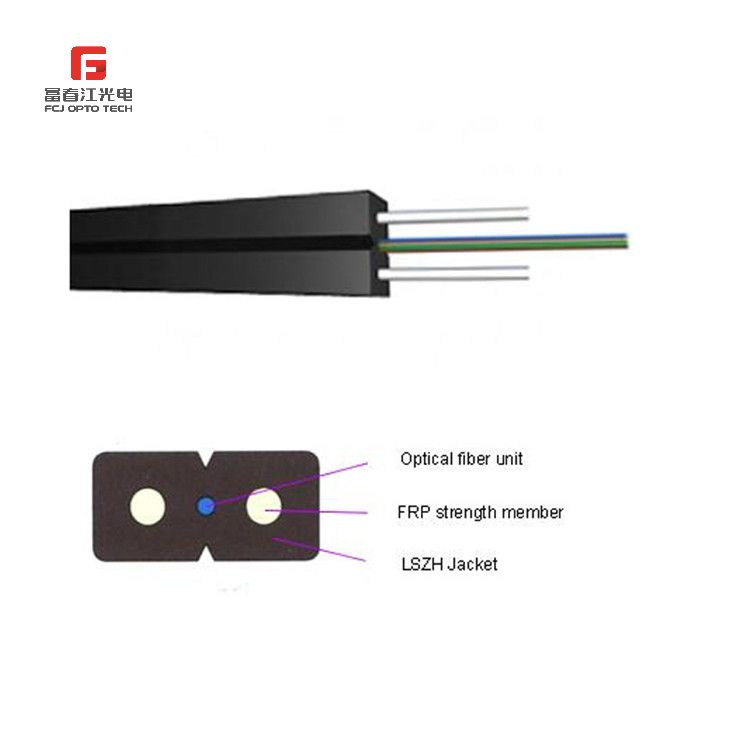

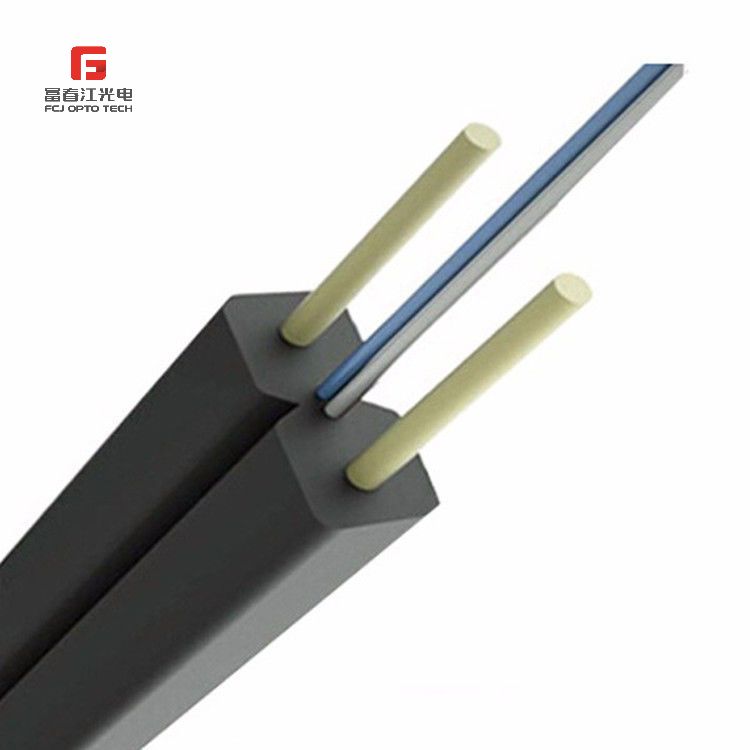

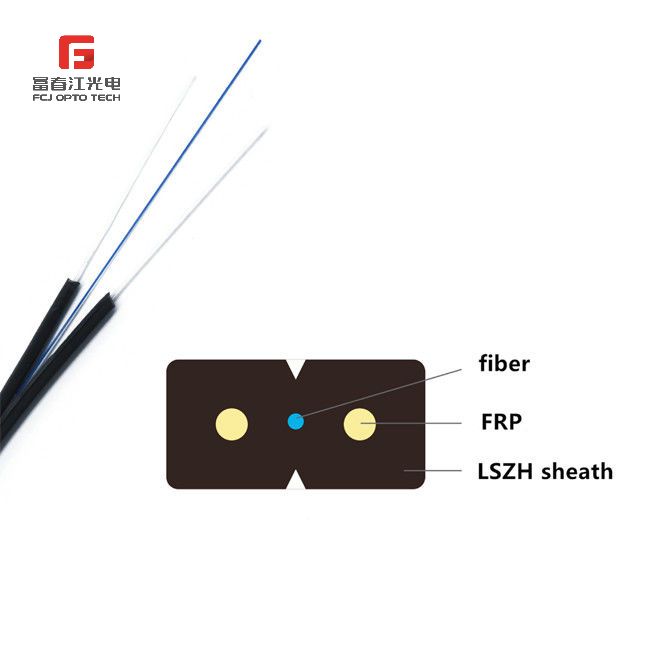

| Model Number | Type | Outer Jacket Material | Strength Member | Fiber Model |

|---|---|---|---|---|

| GJXFH | Fiber Optic Cable | LSZH | FRP | Singlemode G657A1 |

Product Manufacturing Process

Based on current authoritative papers, manufacturing branch cables involves precise processes, ensuring stability and performance. Conductors are selected for optimal electrical conductivity and flexibility, typically copper, which is insulated with materials like PVC to ensure safety and durability. The outer sheath provides protective enclosure, often using robust compounds for enhanced resistance to environmental factors. Rigorous quality control measures are implemented throughout the manufacturing process, ensuring each cable meets the stringent IEC and NEC standards. This thorough process guarantees that the branch cables are reliable and perform efficiently in various conditions.

Product Application Scenarios

Branch cables are pivotal in diverse applications, ranging from residential to industrial settings. They connect main power lines to sub-circuits, facilitating efficient power distribution. In residential systems, they ensure safe power flow to outlets and appliances, while in commercial and industrial environments, they cater to complex distribution needs. Additionally, they are integral to renewable energy systems, connecting solar or wind energy installations to the grid. Telecommunication networks also benefit from robust branch cable solutions, linking network nodes for seamless data transmission.

Product After-Sales Service

We offer comprehensive after-sales service, including technical support, troubleshooting, and replacement services. Our dedicated team is committed to ensuring customer satisfaction and addressing any issues promptly.

Product Transportation

Our branch cables are packaged securely in carton boxes or wooden reels to prevent damage during transit. We coordinate with reliable logistics partners to ensure timely and safe delivery to our customers worldwide.

Product Advantages

- High bandwidth and excellent transmission properties.

- Robust crush resistance and protection from mechanical stress.

- Easy installation with novel flute design.

- Safe with low smoke, zero halogen, and flame-retardant sheath.

Product FAQ

- Q: What are the main components of the branch cable?

A: The branch cable comprises conductors typically made of copper, insulation such as PVC or XLPE, a robust outer sheath, and sometimes an armor layer for enhanced protection.

- Q: What is the tensile strength of the GJXFH branch cable?

A: The GJXFH branch cable offers a tensile strength of 40/80 Newtons, providing robust performance in diverse applications.

- Q: How does the branch cable handle environmental factors?

A: The branch cable is designed to withstand various environmental conditions, thanks to its durable outer sheath and reliable insulation materials, ensuring long-term performance.

- Q: What standards do the branch cables adhere to?

A: Our branch cables comply with NEC and IEC standards, ensuring safety, reliability, and performance across different applications.

- Q: Can these cables be used in renewable energy systems?

A: Yes, our branch cables are well-suited for renewable energy systems, effectively connecting solar panels or wind turbines to the grid.

- Q: What makes the GJXFH branch cable easy to install?

A: The GJXFH branch cable features a novel flute design, simplifying strip and splice operations, making it easy to install and maintain.

- Q: How does the branch cable manage data in telecommunication networks?

A: Though primarily power cables, similar branch cable systems are adapted for data transmission, efficiently linking network nodes.

- Q: What is the operation temperature range for the branch cable?

A: The branch cable can operate within a temperature range from -20℃ to 60℃, ensuring reliable performance in various environments.

- Q: How is the branch cable packaged for delivery?

A: The cables are securely packaged in carton boxes or wooden reels for safe transportation, preventing damage during transit.

- Q: What applications benefit greatly from these branch cables?

A: Applications ranging from residential wiring to industrial setups and telecommunication networks benefit from our versatile and durable branch cables.

Product Hot Topics

- Ensuring Reliable Power Distribution with Branch Cables

In today’s power-centric world, the use of branch cables forms the backbone of efficient power distribution systems. As a leading manufacturer, we provide branch cables that ensure seamless connectivity and power flow across various endpoints, from homes to large industrial facilities. Our products are tailored to perform in diverse scenarios, maintaining reliability even under challenging conditions.

- The Role of Branch Cables in Telecommunication Networks

Branch cables are not just limited to power distribution. With the evolving needs of telecommunication networks, similar cabling systems are adapted to enhance data transmission capabilities. Our branch cables, manufactured to the highest standards, offer robust solutions that support infrastructural needs of modern telecommunication systems, ensuring uninterrupted signal delivery.

- Why Copper is Preferred in Branch Cable Manufacturing

Copper has long been favored in the manufacturing of branch cables, primarily due to its excellent conductivity and flexibility. As a manufacturer, we leverage these properties to produce cables that offer superior performance and adaptability. While aluminum is an alternative, copper remains a top choice for critical applications demanding high reliability and top-notch conductive properties.

- Adapting to Environmental Challenges with Durable Sheathing

Environmental factors pose significant challenges to cable performance. Our branch cables are designed with durable sheathing to counter these risks, offering protection against moisture, chemical exposure, and physical damage. This ensures that performance and safety are not compromised, even in harsh environments, making them a top choice for manufacturers looking for reliable solutions.

- Innovative Design for Ease of Installation

Installation challenges are common in large-scale projects. Our branch cables address this with innovative design features that simplify installation processes. The novel flute design is user-friendly, allowing for easy strip and splice, reducing labor time, and enhancing overall efficiency. As a result, manufacturers consistently choose our cables for projects demanding streamlined installation.

- Understanding the Life Cycle of Branch Cables

Understanding the life cycle of branch cables is crucial for maintenance and planning. As a manufacturer, we provide detailed insights into the durability and longevity of our cables, helping clients anticipate wear and plan for replacements. By adhering to high manufacturing standards, we ensure our branch cables have a prolonged life span, minimizing the need for frequent replacements.

- Branch Cables in Renewable Energy: A Sustainable Choice

The renewable energy sector is rapidly growing, and our branch cables are at the forefront of this change. Specifically designed to integrate with solar and wind energy systems, they ensure efficient connectivity and power distribution. Manufacturers seeking to expand their renewable energy projects rely on our high-quality cables to meet sustainability goals while ensuring robust performance.

- Technical Standards and Safety Regulations

Compliance with technical standards and safety regulations is non-negotiable in cable manufacturing. Our branch cables adhere to stringent NEC and IEC standards, ensuring they meet industry safety and performance requirements. Manufacturers prioritize these standards to maintain credibility and guarantee safety across projects, making our cables a trusted choice in the market.

- Branch Cables: Meeting the Demands of Modern Infrastructure

Modern infrastructure demands high-performance components, and branch cables are no exception. Our product line is engineered to address these needs, offering reliable solutions that meet the complexities of contemporary installations. As a result, manufacturers and project managers prioritize our cables to ensure infrastructure resilience and efficiency.

- Future Trends in Branch Cable Manufacturing

As technology evolves, so do the trends in branch cable manufacturing. Our focus remains on innovation, ensuring our products align with future demands. Exploring advancements in materials and design, we continue to lead the industry, offering manufacturers cutting-edge solutions that future-proof their projects against the backdrop of technological change.

Image Description