GYTS Cable Factory: High-Quality Telecom Solutions

Product Main Parameters

| Parameter | Value |

|---|---|

| Optical Fiber Type | G.652, G.655, 50/125μm, 62.5/125μm |

| Attenuation (20℃) | ≤3.0 dB/km @850nm, ≤1.0 dB/km @1300nm |

| Operating Temperature | -40℃ to 70℃ |

Common Product Specifications

| Specification | Detail |

|---|---|

| Outer Sheath | PE or AT |

| Central Strength Member | Phosphatized Steel Wire or FRP |

Product Manufacturing Process

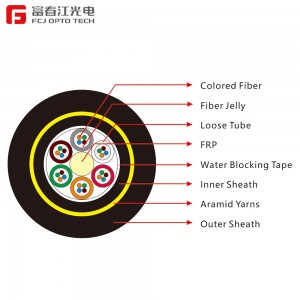

The manufacturing process of GYTS cables involves advanced techniques to ensure high quality and performance. Initially, optical fibers are coated with a protective layer and embedded in loose tubes filled with thixotropic gel to resist moisture. A central strength member is then positioned, and the tubes are stranded around it. A polyethylene sheath is applied for UV protection. According to recent studies, such structured manufacturing results in highly robust and reliable transmission lines capable of enduring harsh conditions while maintaining signal integrity.

Product Application Scenarios

GYTS cables are highly versatile and used in various telecommunication applications. They support long-distance communication in metropolitan networks, backbone installations, and rural deployments. Their resilience makes them suitable for outdoor settings, including LAN/WAN connections and fiber-to-the-x applications. Authoritative papers affirm that GYTS cables are crucial in expanding reliable internet and communication services globally, providing cost-effective solutions without compromising on quality.

Product After-Sales Service

Our factory offers comprehensive after-sales support for GYTS Cable products, including installation guidance, troubleshooting, and maintenance services. Customers can contact our technical support team for any assistance required.

Product Transportation

GYTS cables are shipped using robust packaging to prevent damage during transit. Our logistics team coordinates with reputable carriers to ensure timely and safe delivery to our customers worldwide.

Product Advantages

- Moisture-resistant thixotropic gel ensures fiber protection.

- High tensile strength due to central reinforcement.

- Cost-effective for long-distance installations.

- UV and chemical-resistant PE sheath enhances durability.

- Compatible with a wide temperature range.

Product FAQ

- What materials are used in GYTS cables?

GYTS cables from our factory use high-quality materials like G.652 optical fibers, phosphatized steel or FRP for reinforcement, and a UV-resistant polyethylene sheath. - Can GYTS cables be used in extreme temperatures?

Yes, our factory's GYTS cables are designed to operate efficiently within a temperature range of -40℃ to 70℃, providing reliable performance in diverse environments. - Are these cables suitable for rural areas?

Absolutely. GYTS cables are ideal for rural telecommunications due to their durability and efficiency in remote and harsh conditions. - What is the significance of the central strength member?

The central strength member, made of phosphatized steel or FRP, gives the GYTS Cable robust tensile strength, aiding installation and longevity. - How do GYTS cables resist moisture?

The loose tubes in our GYTS cables are filled with a thixotropic gel that effectively blocks moisture, preserving signal quality. - What measures ensure UV protection?

The outer sheath of GYTS cables is crafted from UV-resistant polyethylene, safeguarding against sunlight exposure. - Why choose non-armored cables?

Non-armored GYTS cables offer a cost-effective solution for long-distance installations where mechanical protection is less critical. - Are there specific installation guidelines?

Yes, install the GYTS cables with considerations for optimal routing, proper handling, and environmental suitability for best performance. - What bandwidth do these cables support?

Our GYTS cables support high bandwidth, ensuring efficient data transmission, suitable for modern telecommunication needs. - How do they compare to other cable types?

GYTS cables from our factory offer an excellent balance of performance, durability, and cost, suitable for extensive telecommunication infrastructures.

Product Hot Topics

- The Future of Telecommunications: The Role of GYTS Cables

The future of telecommunications highly depends on the advancements in cable technology. The GYTS Cable factory is at the forefront, providing innovative solutions that enhance long-distance communication capabilities. With the demand for high-speed internet rising, these cables are set to play a crucial role in infrastructure development worldwide, supporting both urban and rural connectivity goals. - Understanding the Manufacturing Process of GYTS Cables

Our factory utilizes state-of-the-art manufacturing processes for GYTS Cables, adhering to stringent quality standards. This involves precise fiber alignment, moisture-resistant gel filling, and robust sheath application. Understanding these processes highlights the cable's durability and performance attributes, further affirming their value in the telecom industry. - Overcoming Environmental Challenges with GYTS Cable Solutions

GYTS cables are engineered to withstand environmental adversities, such as moisture, UV radiation, and extreme temperatures. This makes them a reliable choice for outdoor installations in diverse climates. Our factory's dedication to quality ensures that each cable provides uninterrupted service, crucial for expanding telecommunication networks. - The Economic Benefits of Choosing GYTS Cables

When selecting telecommunication infrastructure, the cost-effectiveness of GYTS cables is unmatched. Our factory offers these cables at competitive prices without compromising on quality, providing an affordable solution for extensive data network installations, especially in long-distance and harsh outdoor scenarios. - Installation Best Practices for GYTS Cables

The installation of GYTS cables should follow specific guidelines to harness their full potential. Proper routing, minimal bending, and environmental considerations are essential. Our factory provides comprehensive installation support to help customers achieve optimal results, ensuring stable and reliable connections. - Comparing Armored and Non-Armored Cables: GYTS Advantages

Choosing between armored and non-armored cables can significantly impact project costs and efficiency. Non-armored GYTS cables from our factory offer cost benefits while maintaining high performance and durability levels, making them suitable for environments where heavy armor is unnecessary. - The Technological Evolution of GYTS Cable Production

The production of GYTS cables involves continuous innovation. Our factory incorporates the latest technologies to enhance cable performance, durability, and reliability, meeting the ever-evolving demands of modern telecommunications infrastructure. - Exploring Global Connectivity with GYTS Cables

As global connectivity grows, GYTS cables provide the necessary infrastructure for expanding communication networks. Their deployment is crucial in both developed and developing regions, enabling fast and reliable internet access. Our factory is committed to supporting this global expansion with high-quality cable solutions. - Impact of Climate on Telecommunications: The Role of GYTS Cables

Climate challenges pose significant hurdles for telecom infrastructure. However, GYTS cables are designed to withstand extreme conditions, ensuring consistent performance. Our factory's focus on quality and resilience positions these cables as a critical component in all-weather communication networks. - The Lifecycle Management of GYTS Cables

Understanding the lifecycle of GYTS cables helps in planning long-term telecommunication projects. From manufacturing to installation and maintenance, each phase is crucial. Our factory provides insights and support, ensuring that customers maximize the lifespan and efficiency of their cable investments.

Image Description

There is no picture description for this product