Description

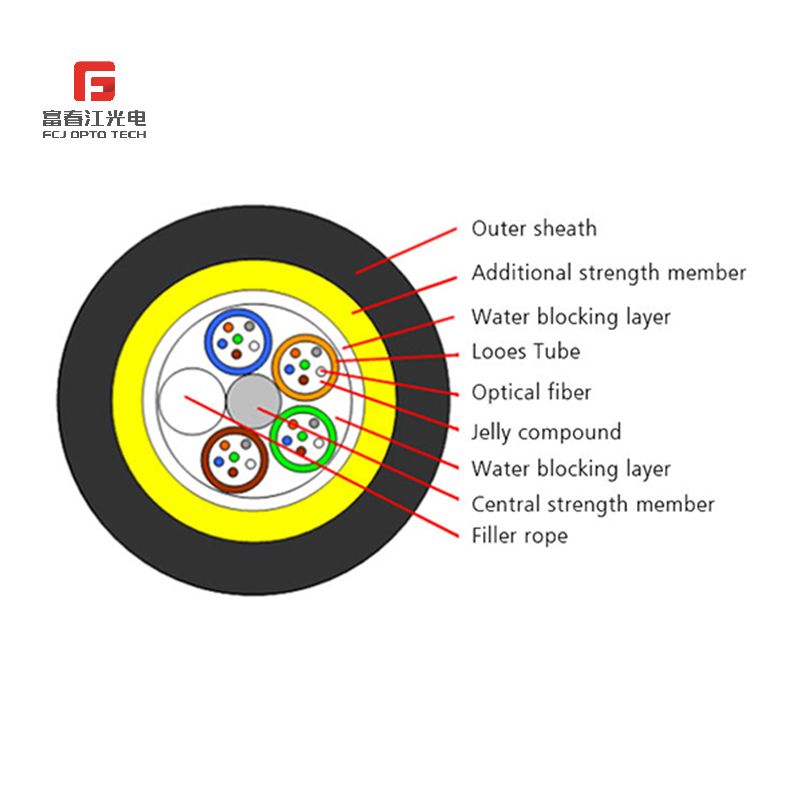

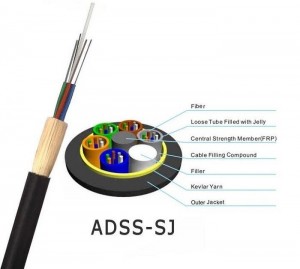

ADSS cable adopts the twisted structure of loose sleeve layer, 250 μm optical fiber is inserted into the loose tube made of high modulus materials, and the loose tube is filled with waterproof compounds. The loose tube ( and filling rope ) is twisted around the non-metallic center reinforcing core ( FRP ) to synthesize a compact cable core. The gap of the cable core is filled with a water-blocking yarn and a water-blocking belt longitudinally wrapped by the cable core, and then the aramid fiber that plays a reinforcing role is twisted. Finally, the polyethylene ( PE ) outer sheath or the electric mark ( AT ) outer sheath is extruded.

Characteristics

· Continuous electrical erection

· Superior resistance to electric marks with AT sheath

· Light weight, small cable diameter, reduced ice, wind impact and load on tower, support

· Excellent tensile and temperature properties

· Life expectancy up to 30 years

Standards

The ADSS cable follows the IEEE P 1222 technical standard, and meets the IEC 60794-1 standard and DLT 788-2016 standard.

Optical Characteristics

|

|

G.652

|

G.655

|

50/125μm

|

62.5/125μm

|

|

@1300nm

|

|

|

≤1.0dB/km

|

≤1.0dB/km

|

|

@1310nm

|

≤0.00dB/km

|

≤0.00dB/km

|

|

|

|

@1550nm

|

≤0.00dB/km

|

≤0.00dB/km

|

|

|

|

Bandwidth(Class A)

|

@850nm

|

|

|

≥500MHz·km

|

≥200MHz·km

|

|

@1300nm

|

|

|

≥500MHz·km

|

≥500MHz·km

|

|

Numerical aperture

|

|

|

0.200±0.015NA

|

0.275±0.015NA

|

|

Cable Cutoff Wavelength

|

≤1260nm

|

≤1480nm

|

|

|

Technical Parameters

|

Cable Diameter

mm

|

Cable Weight

kg/km

|

Recommend maximum working tension

kN

|

Maximum allowable working tension

kN

|

breaking tenacity

kN

|

Section area of tensile components

mm2

|

modulus of elasticity

kN/ mm2

|

thermal expansion coefficient×10-6/k

|

|

PE sheath

|

AT sheath

|

|

9.8

|

121

|

130

|

1.5

|

4

|

10

|

4.6

|

7.6

|

1.8

|

|

10.2

|

129

|

138

|

2.1

|

5

|

14

|

6.9

|

8.1

|

1.4

|

|

13.1

|

132

|

143

|

2.8

|

7

|

19

|

9.97

|

9.13

|

1.2

|

|

15.6

|

189

|

207

|

3.8

|

9

|

26

|

14.2

|

11.2

|

1.0

|