Manufacturer Patch Cord: Indoor Fiber Optic Cable 144 Core

Product Main Parameters

| Parameter | Specification |

|---|---|

| Core Count | 24, 48, 96, 144 |

| Buffer Diameter | 900±50μm |

| Jacket Material | PVC(LSZH) |

Common Product Specifications

| Specification | Value |

|---|---|

| Cable Diameter | 6.5±0.25 mm |

| Cable Weight | 32 kg/km |

Product Manufacturing Process

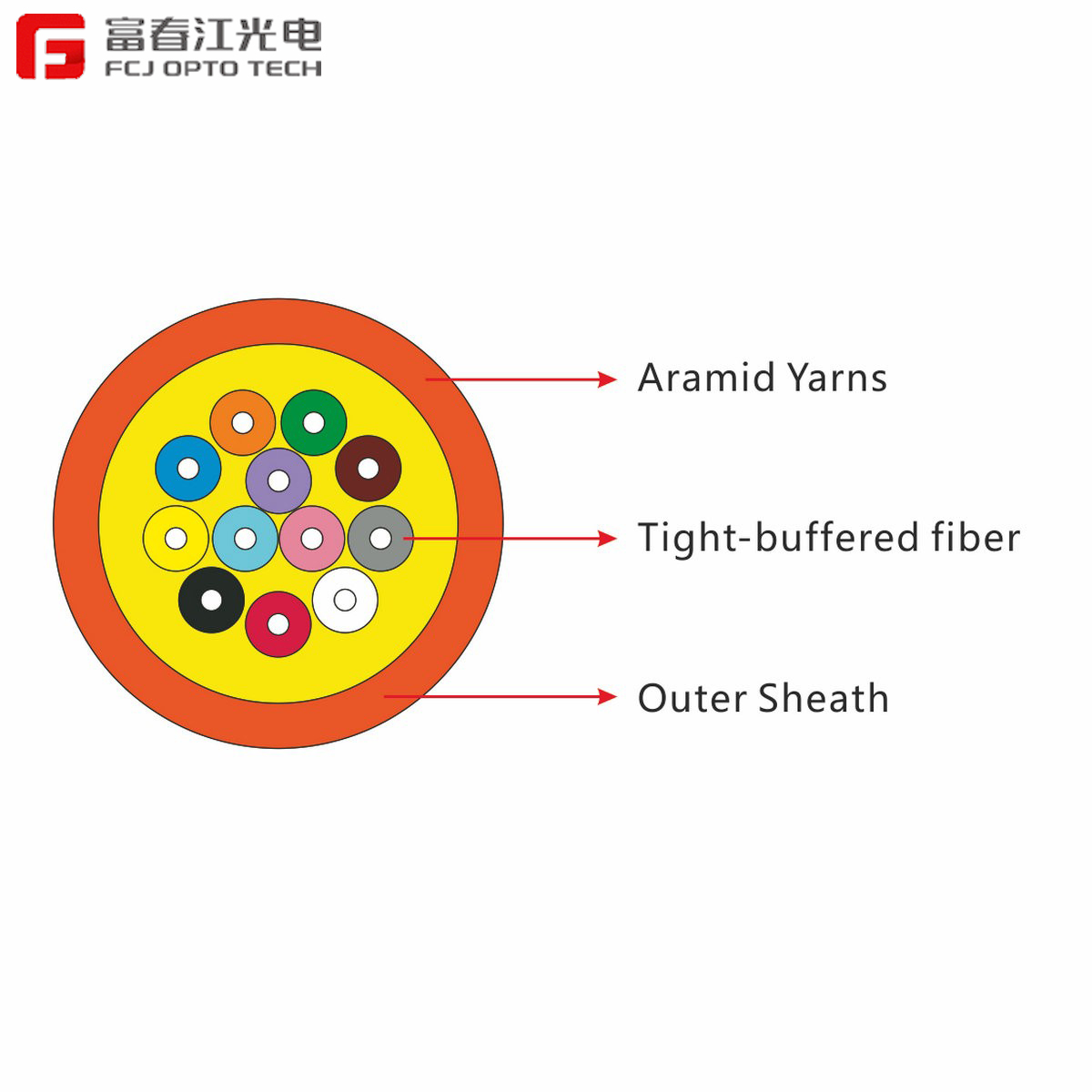

The manufacturing process of our indoor patch cords involves precision engineering and the use of high-quality materials. Adopting techniques outlined in industry-standard papers such as 'Optical Fiber Cable Technology' ensures optimal performance characteristics. The process begins with the selection of high-purity optical fibers, followed by the application of aramid yarns for strength. The fibers are then encased in a tight buffer, and a high-performance PVC (LSZH) jacket is applied to ensure fire resistance and durability. This meticulous process guarantees a product that meets international standards and provides reliable network connectivity.

Product Application Scenarios

The manufacturer patch cord is suitable for indoor distribution, connecting communication equipment, and floor installations. As per studies like 'Fiber Optic Communications' by Palais, the use of indoor patch cords in data centers and telecom rooms is due to their lightweight, flexibility, and reduced signal attenuation. These patch cords are integral in setups requiring reliable, high-speed data connectivity and are favored for their easy installation and maintenance.

Product After-Sales Service

We offer comprehensive after-sales service, including technical support, warranty services, and assistance with installation or troubleshooting, ensuring customer satisfaction with our manufacturer patch cords.

Product Transportation

Our manufacturer patch cords are carefully packaged to prevent damage during transit. They are shipped globally with options for expedited delivery to meet customer needs.

Product Advantages

- High flexibility and low attenuation for reliable connections

- Flame-retardant and environmentally safe LSZH jacket

- Compatible with various network environments

Product FAQ

- What is the maximum length for the patch cord? Our manufacturer can customize lengths to meet your needs, typically ranging from 1m to 100m without significant signal loss.

- Are these patch cords compatible with existing infrastructure? Yes, they meet industry standards, ensuring compatibility with most existing network setups.

- What environments suit these patch cords? They are ideal for indoor use, including offices, data centers, and telecom rooms.

- Do you provide technical support for installation? Yes, our manufacturer offers comprehensive technical support to assist with installation and maintenance.

- What is the expected lifespan of the patch cord? Designed for longevity, they can last several years under standard usage conditions.

- How do I choose between single-mode and multi-mode? It depends on your network needs—single-mode for long-distance, multi-mode for shorter connections.

- Can these cords be used outdoors? While designed for indoor use, specific environmental conditions may allow limited outdoor use with precautions.

- Are there different color options available? Yes, we offer a variety of color options to match network aesthetics and improve cable management.

- What testing is performed on the cords? Each cord undergoes rigorous testing for durability, performance, and compliance with standards.

- Can I return the product if it doesn't meet my needs? Yes, we have a flexible return policy. Contact us for more details.

Product Hot Topics

- The Rise of Manufacturer Patch Cords in Data Centers As data centers evolve, the demand for high-quality manufacturer patch cords increases. These cords ensure connectivity and adaptability, vital for efficient data handling and management. FCJ OPTO TECH's patch cords stand out for their reliability and performance, suiting various network configurations.

- Innovative Manufacturing Processes in Optical Cables With advancements in technology, the manufacturing process of fiber optic cables, including patch cords, has seen significant improvements. The use of high-grade materials, precision engineering, and compliance with global standards make manufacturer patch cords essential for modern networks.

Image Description