Understanding the Structure of Outdoor Fiber Cables

Core Components and Their Roles

Outdoor fiber optic cables, particularly the 2-core variants, are designed to withstand harsh environmental conditions. The core of the cable is typically made of high-purity silica, which ensures minimal signal loss and enables long-distance transmission. This core is surrounded by cladding with a slightly lower refractive index to keep light signals intact.

Importance of Protective Buffers

The buffer coating plays a crucial role in protecting the optical fiber. It guards against moisture ingress and mechanical damages. Manufacturers often use UV-cured acrylate coatings because of their excellent protective properties and resistance to environmental stress.

Material Selection for Durability

High-Quality Raw Materials

Manufacturers and suppliers prioritize the use of high-quality raw materials such as quartz, which is a critical component for optical fibers. The selection of pure and high-grade materials reduces the likelihood of imperfections that could weaken the cable.

Advanced Optical Glass

The choice of optical glass impacts the performance and durability of fiber cables. Factories often use highly refined silica with low impurities to ensure the fiber can withstand the rigors of outdoor environments while maintaining excellent signal transmission capabilities.

Protective Layer Innovations for Outdoor Cables

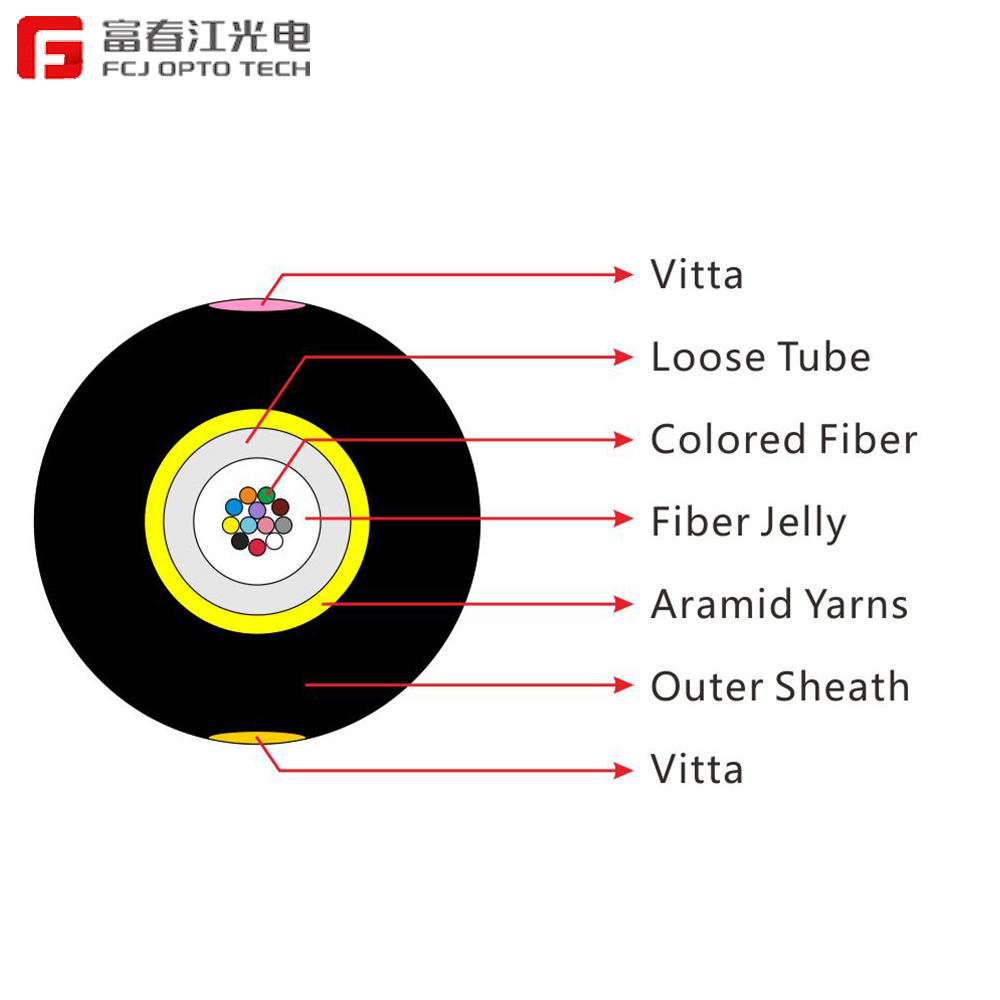

Multi-Layered Protection

To withstand harsh conditions, outdoor cables are equipped with multiple protective layers. These layers include water-blocking tapes, moisture-resistant coatings, and robust outer jackets made from polyethylene or other durable polymers.

UV and Chemical Resistance

The outer jackets of outdoor cables are designed to resist ultraviolet radiation and chemical exposure. This is particularly important in environments with high solar exposure and potential chemical pollutants, ensuring the cable remains functional over extended periods.

Non-Metal Reinforcement

Strength Members for Added Durability

To reinforce the cables without adding weight, manufacturers use non-metallic strength members like aramid yarns. These materials provide excellent tensile strength, making the cables suitable for aerial installations where wind loads can exert significant force.

Rodent and Pest Resistance

Fiber optic cables are vulnerable to rodent damage in certain environments. By using specially designed non-metallic armors, manufacturers can enhance the cables' resistance to such threats, ensuring longevity and reduced maintenance needs.

Manufacturing Techniques That Enhance Durability

Precision Manufacturing Processes

Manufacturers employ precision techniques in the drawing and coating processes to maintain the structural integrity of the fiber. This meticulous attention to detail helps in reducing microbends and macrobends, which can lead to signal loss.

Environmental Testing

Before deployment, cables undergo rigorous testing for environmental resilience, including thermal cycling and moisture exposure tests. These tests help ensure that the cables can withstand the challenging outdoor conditions they will face.

Ensuring Tensile Strength in Fiber Cables

Tensile Load Bearing Capacity

Manufacturers design cables to have high tensile load-bearing capacities, often measured in hundreds of Newtons. This capability is critical for installations where the cable is subject to pulling during installation or tension during operation.

Impact of External Forces

The ability to absorb and withstand external forces without deformation or breakage is vital. Factors such as wind, ice, and mechanical impacts are simulated to test the cable's durability under real-world conditions.

Environmental Resistance: A Key Attribute

Temperature Tolerance and Fluctuations

Outdoor fiber cables are engineered to operate within a wide temperature range, typically from -40°C to +70°C. This allows them to perform efficiently in both polar environments and desert conditions.

Moisture and Water Resistance

Moisture resistance is achieved through the use of water-blocking gels and tapes. These features prevent water ingress that can cause attenuation and potential cable failure, ensuring reliable performance even in high-humidity areas.

Quality Control in Fiber Cable Production

Stringent Manufacturing Standards

Manufacturers adhere to international standards like ISO and IEC to ensure the production of high-quality cables. Regular audits and quality checks during the manufacturing process help in maintaining these standards.

Continuous Monitoring and Improvement

Suppliers invest in continuous monitoring systems for quality control. Data collected from these systems is used to refine processes and improve the overall durability and reliability of fiber cables.

Innovations in Fiber Optic Cable Jackets

Enhanced Material Properties

The development of advanced materials for outer jackets has significantly improved cable durability. These innovations include the use of carbon black for UV resistance and advanced polymers for abrasion resistance.

Customization for Specific Uses

Manufacturers offer customized solutions for specific applications, such as armored cables for rocky terrains or cables designed for high-altitude installations, ensuring that the right product is available for every environmental challenge.

Application-Specific Design Considerations

Adapting to Installation Environments

The choice of cable design is influenced by the installation environment. Factors such as the presence of wildlife, temperature extremes, and mechanical stressors are considered to ensure optimal performance.

Connectivity and Scalability

Manufacturers design cables with future scalability in mind. This includes considerations for expanding network capacity or adapting to new technologies, ensuring that the infrastructure remains robust and relevant.

Future Trends in Fiber Cable Durability

Integration with Smart Technologies

Emerging trends in fiber optic cable design focus on integrating smart technologies that monitor cable health and performance in real-time. This proactive approach helps in predicting maintenance needs before substantial issues arise.

Focus on Sustainability

Sustainability in fiber optic cable manufacturing is gaining attention, with an emphasis on reducing environmental impact through the use of recyclable materials and energy-efficient production techniques.

Fcjoptic Provide Solutions

Fcjoptic is committed to offering robust solutions for outdoor fiber optic cable durability. By employing state-of-the-art materials and advanced manufacturing processes, we ensure that our cables withstand the toughest environmental challenges. Our dedicated research and development team continuously innovates, focusing on enhancing strength and resilience while reducing environmental impact. Whether you need cables for extreme temperatures or high-stress applications, Fcjoptic provides tailored solutions to meet your specific requirements.

User hot search: 2core Outdoor Fiber Cable

Post time: 2025-09-30 09:21:06