Premium Quality Outdoor Mini Air-blown Optical Fiber Cable at an Affordable Optical Splitter Price

Characteristics

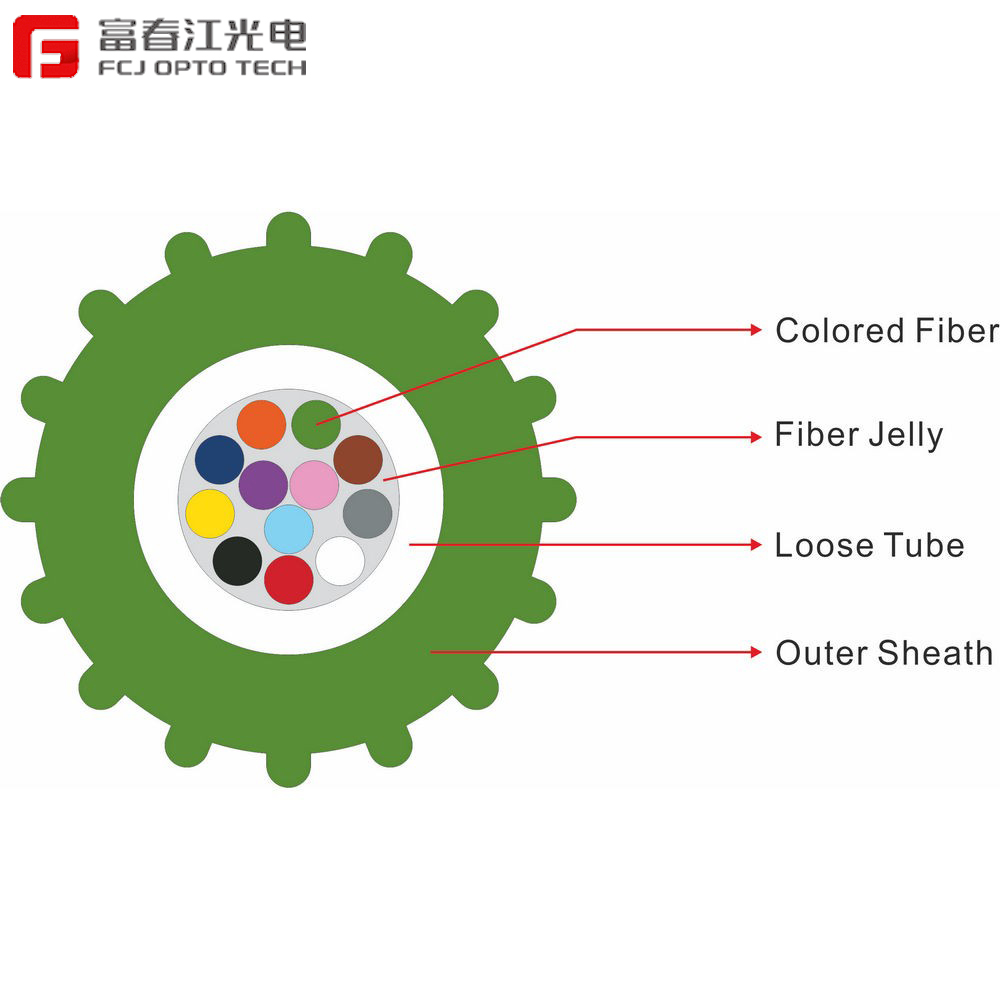

- Special composite material loose casing to reduce low temperature casing retraction.

- Precise control of fiber residual length, stable performance of optical cable.

- Unique process control to eliminate sheath wrinkling in air blowing.

- High density polyethylene outer sheath to improve air blowing distance.

-

Standards

IEC 60794-5、IEC 60794-1-2 or D/T 1460-2006

Optical Characteristics

|

|

G.652 |

G.655 |

50/125μm |

62.5/125μm |

|

|

Attenuation (+20℃) |

@850nm |

|

|

≤3.0dB/km |

≤3.0dB/km |

|

|

@1300nm |

|

|

≤1.0dB/km |

≤1.0dB/km |

|

|

@1310nm |

≤0.36dB/km |

≤0.36dB/km |

|

|

|

|

@1550nm |

≤0.22dB/km |

≤0.23dB/km |

|

|

|

Bandwidth (Class A) |

@850 |

|

|

≥500MHZ·km |

≥200MHZ·km |

|

|

@1300 |

|

|

≥1000MHZ·km |

≥600MHZ·km |

|

Numerical Aperture |

|

|

|

0.200±0.015NA |

0.275±0.015NA |

|

Cable Cut-off Wavelength λcc |

|

≤1260nm |

≤1480nm |

|

Technical Parameters

|

Mini Cable Type |

GCYFXY-xxF(MTE +Outer diameter) |

||||

|

|

MTE1.8 |

MTE2.0 |

MTE2.3 |

MTE2.5 |

MTE2.8 |

|

Fiber Count |

2~4 |

2~4 |

6~12 |

2~12 |

14~24 |

|

HDPE Outer Sheath Thickness |

Nominal:0.20mm,Mini: 0.15mm |

||||

|

Nominal Outer Diameter |

1.8mm |

2.0mm |

2.3mm |

2.5mm |

2.8mm |

|

Approximate Weight |

2.6 kg/km |

4.0 kg/km |

5.0 kg/km |

6.0 kg/km |

7.0kg/km |

|

Attenuation (single-mode fiber) |

1310nm/1550nm≤0.35/0.22dB/km |

||||

|

Max. Pulling Force |

40N |

40N |

50N |

60N |

60N |

|

Max. Squeeze Force |

600N/100mm |

||||

|

Mini Permissible Static / Dynamic Bending Radius |

10x/20x O.D. of fiber optic cable |

||||

|

Temperature Range |

Storage -30~+60℃; Installation -10~+40℃; Operation -20~+50℃ |

||||

|

Fiber optic cable life (valuation) |

25 YEARS |

||||

Mechanical performance

|

Items |

Test Reference Standards |

Test Results |

Remarks |

||

|

Tension |

IEC 60794-1-2-E1 (GB/T 7424.2-E1) |

Fiber Strain(%) |

Accessory Decay(dB) |

Short-term test tension is the maximum tension. Long-term test tension is 1/3 of the maximum tension |

|

|

|

Short-term ≤0.3 Long-term ≤0.1 |

Short-term:≤0.1, No significant strain after stress relief; Long-term:No Significant |

|

||

|

Flattening force |

IEC 60794-1-2-E3 (GB/T 7424.2-E3) |

Short-term crushing force: additional attenuation ≤ 0.05. Long-term crushing force: no significant. After stress removal, no visible residual additional attenuation of the fiber, the No visible cracking on the sheath surface |

Short-term test pressure:600N Long-term test pressure: 200N |

||

|

Repeated bending Test |

IEC 60794-1-2-E6 (GB/T 7424.2-E6) |

After testing: no visible residual accessory attenuation of the fiber. No visually visible cracking of the sheath |

Bending radius = 20 times the diameter of the micro cable |

||

|

|

|

|

Load = 15N |

||

|

|

|

|

Bending times: 25 |

||

|

Torsion test |

IEC 60794-1-2-E7 (GB/T 7424.2-E7) |

After the test: no fiber breakage and no visually visible cracking of the sheath. After stress removal, no obvious residual additional attenuation |

Turning angle: ±180º |

||

|

|

|

|

Load = 15N |

||

|

|

|

|

Number of torsions: 5 |

||

|

Winding test |

IEC 60794-1-2-E11A (GB/T 7424.2-E11A) |

After the test: no fiber breakage and no visually visible cracking of the sheath |

Mandrel diameter = 20 times the diameter of the micro cable |

||

|

|

|

|

Number of tightly wound turns = 10 |

||

|

|

|

|

Number of cycles = 5 |

||

|

All the above results are tested at 1550nm wavelength |

|||||

Blowing Performance

|

Test Equipment |

Typical air delivery lengths and pipe types suitable for air delivery |

||

|

Polimente: PRM-196 , PR140 etc. Air pressure: 13bar |

Fiber Count |

Microtube type 3.5/5.0mm |

Microtube type 5.5/7.0mm |

|

2~12 core |

800m |

1500m |

|

|

14~24 core |

500m |

1500m |

|

Environmental Characteristics

|

Items |

Test Method |

Indicators to be achieved by the test |

|

Temperature Performance |

IEC 60794-1-2-F1 |

Additional attenuation of fiber (1550nm) |

|

≤0.1 dB/km |

||

|

Water penetration performance |

IEC 60794-1-2-F5B |

1m water height, 3m cable, test time 24 hours No water seepage from the other end of the micro cable |

|

Drip performance |

IEC 60794-1-2-E14 |

Microcables are maintained at an ambient temperature of 70°C for 24 hours No filler compound drops out of microcables |

Embedded within the product is a special composite material that forms a loose casing around the fiber cable. This unique feature significantly reduces any contraction in cold temperatures, making it a reliable choice for outdoor installations. Additionally, its robust design ensures that it withstands the harsh conditions of the external environment, maintaining its performance and durability. Fcjoptic is committed to providing state-of-the-art fiber cables to cater for the demanding needs of the global market. As an SEO worker, we stay tuned to the changing market trends to provide our customers with the most advanced and affordable solutions. With our Outdoor Mini Air-blown Optical Fiber Cable, we are proud to introduce you to a product that promises uncompromised performance at an unbeatable Optical Splitter Price. Embrace the future of fiber cables with Fcjoptic today.