Supplier of Direct Buried Fiber Optic Cable - GJSFJBV

Product Main Parameters

| Parameter | Specification |

|---|---|

| Cable Type | GJSFJBV |

| Tight Diameter | 0.6mm |

| Cable Diameter | 3.0*6.1mm |

| Cable Weight | 43Kg/km |

| Tensile Strength (Long/Short Term) | 300/750N |

| Crush Resistance (Long/Short Term) | 200/1000N/100m |

| Bending Radius (Static/Dynamic) | 20H/10H |

Common Product Specifications

| Optical Characteristics | Specification |

|---|---|

| Attenuation (20℃) @850nm | ≤3.0dB/km |

| Attenuation (20℃) @1300nm | ≤1.0dB/km |

| Bandwidth (Class A) @850 | ≥500MHZ·km |

Product Manufacturing Process

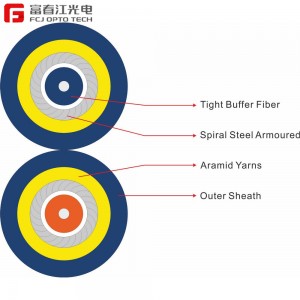

Direct buried fiber optic cables are meticulously engineered to endure underground conditions while maintaining high signal integrity. The manufacturing process begins with the selection of high-quality optical fibers and robust armoring materials like stainless steel wires for enhanced durability. Each fiber is then coated with a water-blocking gel or tape for moisture resistance, which is crucial for maintaining performance in damp environments. The core fibers are encapsulated in a tight buffer and further surrounded by an aramid yarn that provides tensile strength and flexibility. Finally, an outer sheath of PVC or LSZH is applied to ensure flame retardancy and environmental protection. This comprehensive process yields a cable that can successfully withstand mechanical stresses, temperature fluctuations, and potential chemical exposure, providing reliable data transmission over long distances.

Product Application Scenarios

Our supplier-direct buried fiber optic cables are primarily used in challenging installation settings where traditional cabling solutions would be impractical or costly. Ideal for rural telecommunications networks and urban infrastructures, these cables serve as the backbone for data and voice transmission across great distances. Their durability makes them perfect for environments prone to environmental extremities, such as deserts or frozen grounds. Moreover, industries requiring high-performance data transmission in critical operations, like financial institutions and government agencies, trust direct buried fiber optic cables for their reliability and low latency. As telecommunications continue to expand, the demand for such resilient cabling solutions that balance cost-effectiveness and environmental sustainability is bound to increase.

Product After-Sales Service

At FCJ OPTO TECH, our commitment as your supplier extends beyond just delivering direct buried fiber optic cables. We provide comprehensive after-sales support, including installation guidance, technical troubleshooting, and regular maintenance checks. Should any issues arise, our dedicated support team is available 24/7 to ensure seamless operation and customer satisfaction.

Product Transportation

To ensure the safe and timely delivery of our direct buried fiber optic cables, we partner with trusted logistics providers specializing in handling delicate telecommunications equipment. Each shipment is carefully packaged to prevent damage during transit, and we provide tracking services to keep you updated throughout the shipping process, ensuring that your order arrives securely and on schedule.

Product Advantages

- Cost-effective due to minimal use of protective conduits.

- Environmentally friendly with reduced impact on landscapes.

- Highly durable with superior mechanical and environmental resistance.

- Reliable performance across a wide range of temperatures.

- Complies with international standards for quality assurance.

Product FAQ

- What is direct buried fiber optic cable? Direct buried fiber optic cables are designed to be installed directly into the ground without protective conduits. They offer a cost-effective and robust solution for long-distance data transmission.

- How does the cable resist environmental factors? Our cables are armored with durable compounds and feature water-blocking gel or tape, ensuring resilience against moisture, mechanical stress, and extreme temperatures.

- What applications are these cables suitable for? They are ideal for rural networks, urban infrastructure, and industries requiring high-reliability data transmission such as finance and government sectors.

- How to ensure the best installation results? Follow best practices for route planning, trenching, laying, and backfilling. Adhering to installation guidelines maximizes cable longevity and performance.

- Can these cables be repaired? While direct burial provides durability, repairs can be complex due to the need for excavation. Proper planning and installation minimize potential damage.

- What is the lifespan of these cables? With proper installation and minimal mechanical impact, direct buried fiber optic cables can last 20-30 years, offering a long-term solution for telecom infrastructure.

- Is regular maintenance required? While they require less frequent maintenance than exposed cabling, periodic inspections using advanced fault detection technology can ensure continued performance.

- How does temperature affect these cables? Designed for a wide temperature range, our cables maintain performance from freezing winters to hot summers, ensuring reliability in diverse climates.

- Are there aesthetic or environmental benefits? Yes, with no visible infrastructure, they preserve landscape aesthetics and are considered environmentally friendly compared to aerial installations.

- What standards do the cables comply with? Our cables meet standards such as YD/T 2488-2013, ICEA-596, GR-409, and IEC794, guaranteeing quality and safety across global markets.

Product Hot Topics

- Durability of Direct Buried Fiber Optic Cable Direct buried fiber optic cables are a staple of modern telecom infrastructure due to their exceptional durability. Encased in robust materials like stainless steel, these cables resist mechanical stresses, moisture ingress, and extreme temperatures. A supplier's ability to deliver reliable cables can significantly reduce maintenance costs, offering a long-term solution that withstands environmental challenges and ensures stable data transmission over decades.

- Cost Efficiency in Telecommunications As economic pressures rise, finding cost-effective solutions becomes paramount. Direct buried fiber optic cables present a financially viable option by eliminating the need for conduits and reducing installation labor. Partnering with a dependable supplier can further streamline costs, providing high-quality cables that maintain performance and reliability, making them an ideal choice for expansive network projects.

- Environmental Impact and Sustainability With growing emphasis on sustainability, the environmental impact of telecom infrastructure is under scrutiny. Direct buried installations offer a more environmentally conscious alternative by minimizing above-ground installations and preserving the landscape. Suppliers committed to sustainability promote these benefits, ensuring that telecommunications advancements align with ecological considerations.

- Advancements in Installation Technology Technological advancements are improving the installation process for direct buried cables, offering more precise trenching and laying techniques. Suppliers that incorporate these innovations streamline deployments, resulting in faster, more efficient network rollouts and reduced risk of cable damage, vital for expanding connectivity in diverse terrains.

- Temperature Tolerance and Performance Climate extremes demand reliable telecom infrastructure. Direct buried cables excel in this regard, maintaining operational integrity across wide temperature ranges. A supplier's provision of temperature-tolerant cables ensures uninterrupted service, essential for maintaining communication lines during adverse weather conditions.

- Application Versatility of Fiber Optic Cables The versatility of direct buried fiber optic cables allows them to cater to various industries, from telecommunications to critical infrastructure. A dedicated supplier can tailor solutions to meet specific industry needs, reflecting the adaptability of these cables to diverse operational demands, enhancing their market appeal.

- Challenges in Repair and Maintenance While robust, repairs to direct buried cables can be challenging due to their underground placement. Suppliers emphasize the importance of proactive maintenance and advanced monitoring technologies to detect and resolve issues swiftly, minimizing downtime and extending the lifespan of the network infrastructure.

- International Standards and Compliance Adherence to international standards is crucial for global deployment of fiber optic cables. Suppliers offering compliant products ensure safety and quality, facilitating cross-border collaborations and instilling confidence in telecommunications operators looking to expand their reach.

- Role in Urban and Rural Connectivity Bridging connectivity gaps between urban and rural areas is a global priority. Direct buried fiber optic cables are instrumental in this effort, offering a reliable and cost-effective means to extend high-speed internet to underserved regions. Suppliers play a crucial role in supporting these initiatives, offering scalable solutions tailored to diverse connectivity needs.

- Future Trends in Fiber Optic Technology As telecommunications technology evolves, fiber optic cables continue to advance, with suppliers at the forefront of innovations. These include enhanced materials for greater durability, improved installation techniques, and developments in data transmission capabilities, shaping the future of global connectivity.

Image Description

There is no picture description for this product